ABOUT

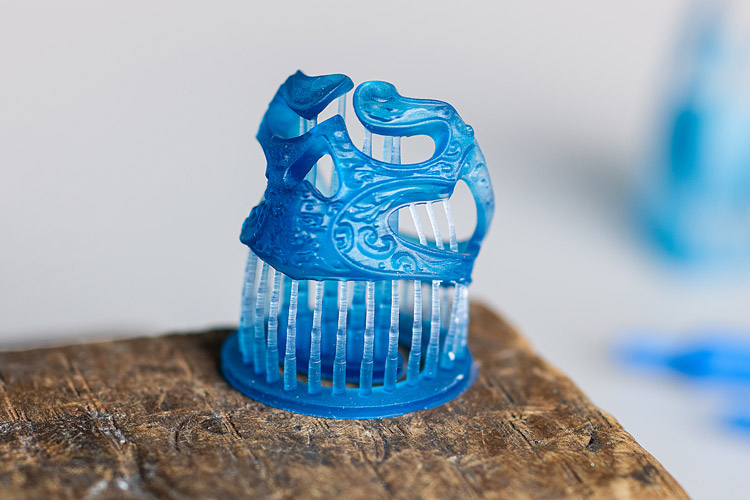

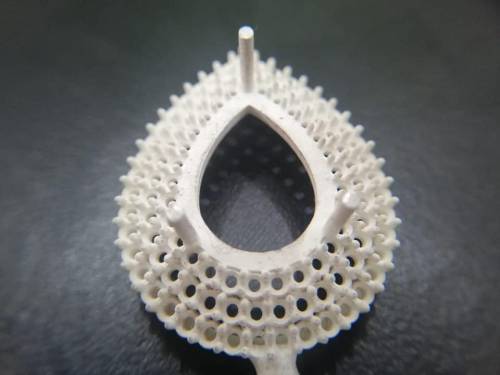

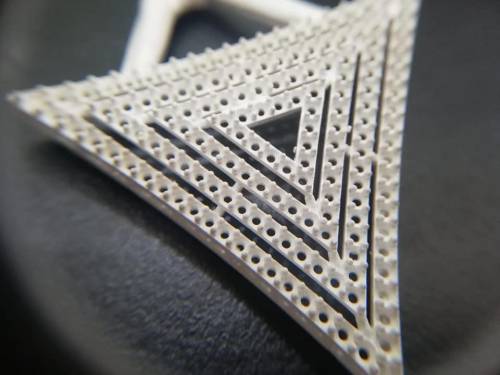

BlueCast X5 has been designed in order to help jewelers in realizing difficult models where dimensional accuracy and structural qualities are required. X5 is raw material based on a synthetized oligomer produced by BlueCast, for which patent is going to be applied. Thank to this resin, it is possible reach outstanding direct casting quality with any type of investment. X5 fits all jewelry needs from filigree to medals as well dental ones. Printed parts are strong enough to be handled without post-cure process, allowing for a faster, simpler workflow.

�

HOW TO USE IT

CRAFTEN X5

BEFORE PRINT

- Preheat the resin to 40°C (104°F). You can heat the resin by submerging the capped bottle in an ultrasonic cleaner or using a baby bottle warmer. Alternatively, you can microwave the completely full 500g bottle (capped) for 45 seconds at 700W. It is important to gradually reduce the heating time based on the bottle weight and resin consumption.

- Before using the resin, shake the bottle for 60 seconds. If the resin has been sitting in the tank, use a silicone spatula to ensure thorough mixing.

- Check the Z offset and calibrate if necessary. For better adhesion, you can use sandpaper (200-400 grit) to abrade the aluminum plate. If you don't have Primercat you can use standard resin or UV glue as well.

- Avoid storing the resin in the resin tank for more than 24 hours, as BlueCast resins are highly hygroscopic and absorbs moisture from the air.

- It is advisable to filter the resin after each print cycle and store it in its original container to preserve its characteristics and prevent alterations. A HD FEP is also recommended to improve the printing quality and platform adhesion. It is recommended to pre-scale the model by +2% to compensate for resin shrinkage.

POST-PRINTING CLEANUP

- Clean the prints using 91%/99% ethyl alcohol or IPA.

- After the first cleaning step, spray brand new 91%/99% ethyl alcohol or IPA over the patterns.

- For optimal results, dry and clean the pieces using a can of compressed air.

- UV post-curing is not necessary unless the pieces require hand-finishing or in case of uncured resin after incomplete washing.

- Proceed with the usual investment process and burn out the pieces.

- Follow the manufacturer's recommended burnout cycle for your chosen investment.

FAST BURNOUT ALLOWED

- The ideal temperature for burning out BlueCast X5 resin is 850°C or 1560°F.

- For fast burnout, it is necessary to use an investment that can withstand temperatures above 850°C. We recommend using high-quality investment or a phosphate-based one.

- To achieve a fast burnout schedule, allow the flask/investment rest for at least 120 minutes. Preheat the kiln to 850-860°C (1560-1580°F), then insert the cylinder and maintain a constant temperature for 120/180 minutes. Reduce the temperature to your casting temperature and hold it for 60 minutes before casting as usual.

- During the initial burnout, position the flask on its side, and then turn it with the button facing up for the rest of the cycle to ensure proper airflow.